Process Development

Optimising Productivity, Resources and Quality

CERASUS solves problems in such a way that it fits seamlessly into the client's overall concept.

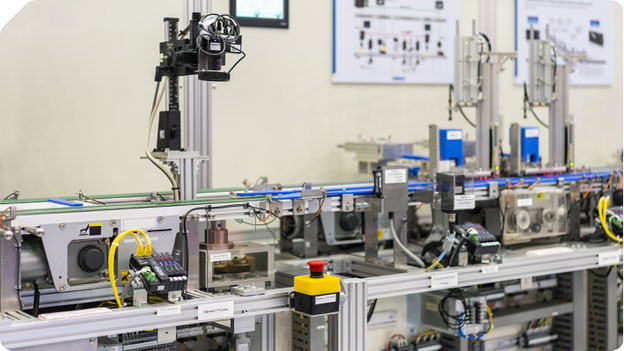

The assembly of a seal, the gluing of two materials, the mechanical joining of a sleeve, the forming of material, the series assembly of an assembly group, the testing of a force threshold, the application of grease or oil, the thermal treatment of a material, the visual inspection of quality features or the flawless monitoring of a system.

These are all processes that are carried out daily in production, and many questions relevant to the end-user are associated with such processes:

- Do rejects or production errors have to be systematically minimized?

- Does the result depend on (individual) people?

- Does the quality have to be reliably proven for the end customer?

- Is an MSA (measurement system analysis) or calibration required?

- Is the manual and unlogged process step relevant to the safety of the end product?

- Is a recurring error pattern in production inexplicable?

With competent team members and fresh ideas for your production, CERASUS helps you to pursue these questions, to look for solutions and to implement them.

CERASUS offers:

- Analytical observation and analysis of existing processes

- Create and analyse temporary records

- Recreate processes and optimize parameters

- Develop and document process validations

- Integration of automatism in quality control

- Proposed solutions for process simplifications through product adjustments

- Project management (overall and sub-projects) for process developments of all kinds - in planning, during execution, in qualification or certification

As a result, the use of resources can be optimized, leading to increased accuracy, productivity, and quality – to more satisfied customers!

Kontakt

CERASUS GmbH

Breitenstrasse 31

CH-6422 Steinen

Mail: cerasus@cerasus.ch

Tel. +41 41 510 04 30

News

19.07.2024 -> 🛠️ Skizzieren und Schemadarstellungen: Effizienz in technischen Diskussionen 📐

Technische Fragestellungen und Herausforderungen werden oft ausgiebig ... >mehr

12.07.2024 -> 🌟 Prüfzelle mit Helium und Argon für die Produktion 🌟

Cerasus hat von der Idee bis zur Inbetriebnahme alles aus einer Hand geliefert. Unsere ... >mehr

21.06.2024 -> 🚀 Willkommen Jonas im CERASUS-Team! 🎉

Seit dem 1. März 2024 verstärkt Jonas Arnold unser Team. Mit seinem breiten Interesse als ... >mehr

20.06.2024 -> 🚲🎷🧆🍻

Unser Cerasus-Team unternahm einen fantastischen Team-Ausflug nach St. Gallen! >mehr